Five dimming methods give you a comprehensive understanding of LED lighting!

Views : 561

Author : Crownda.LED

Update time : 2021-08-14 11:42:41

Five dimming methods give you a comprehensive understanding of LED lighting!

The light-emitting principle of LED is different from that of traditional lighting. It relies on the PN junction to emit light. The LED light source of the same power uses different chips and different current and voltage parameters, so its internal wiring structure and circuit distribution are also different, resulting in different Manufacturers' light sources have different requirements for dimming drive. Therefore, the mismatch of control systems and light source appliances has become a common problem in the industry. At the same time, the diversification of LEDs also poses higher challenges to the control system. If the control system and LED lighting equipment are not matched, it may cause the LED lights to go out or flicker, and may cause damage to the LED drive circuit and light source.

The light-emitting principle of LED is different from that of traditional lighting. It relies on the PN junction to emit light. The LED light source of the same power uses different chips and different current and voltage parameters, so its internal wiring structure and circuit distribution are also different, resulting in different Manufacturers' light sources have different requirements for dimming drive. Therefore, the mismatch of control systems and light source appliances has become a common problem in the industry. At the same time, the diversification of LEDs also poses higher challenges to the control system. If the control system and LED lighting equipment are not matched, it may cause the LED lights to go out or flicker, and may cause damage to the LED drive circuit and light source.

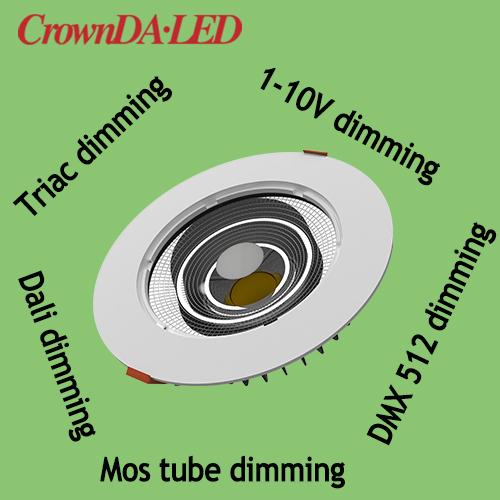

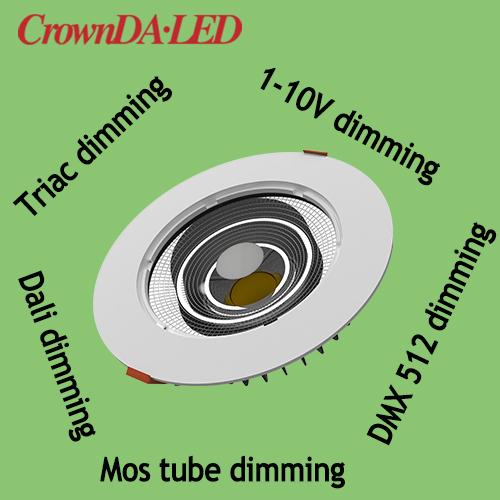

There are five LED lighting control methods on the market:

1. Leading edge phase cut (FPC), Triac dimming or thyristor dimming

Leading edge dimming is to use a thyristor circuit, starting from AC phase 0, the input voltage is chopped, and there is no voltage input until the thyristor is turned on. The principle is to adjust the conduction angle of each half wave of the alternating current to change the sine waveform, thereby changing the effective value of the alternating current, so as to achieve the purpose of dimming.

Cutting-edge dimmers have the advantages of high adjustment accuracy, high efficiency, small size, light weight, and easy long-distance operation. They are dominant in the market, and most LED light manufacturers' products are this type of dimmers. Leading-edge phase control dimmers generally use thyristors as switching devices, so they are also called thyristor dimmers.

The advantages of using FPC dimmers on LED lighting are: low dimming cost, compatibility with existing circuits, and no need to rewiring to control dimming along the phase-cutting edge. The disadvantage is that the FPC's dimming performance is poor, which usually leads to a reduction in the dimming range and causes the minimum required load to exceed the rated power of a single or a small number of LED lighting lamps. Because of the properties of the SCR semi-controlled switch, it only has the function of turning on the current, but not completely shutting off the current. Even if it is adjusted to the lowest level, there is still a weak current passing, and the light-emitting characteristics of the LED's micro-current makes the use of thyristor dimming a large number of The phenomenon of weak light emission still exists after the LED is turned off, which has become a problem in the promotion of the current wiring-free LED dimming method.

2. 1-10V dimming

There are two independent circuits in the 1-10V dimming device, one is an ordinary voltage circuit, used to turn on or off the power supply to the lighting equipment, and the other is a low-voltage circuit, which provides a reference voltage to tell the lighting equipment dimming level , 0-10V dimming controllers were commonly used in the dimming control of fluorescent lamps before. Now, because the constant power supply is added to the LED driver module and there are special control circuits, 0-10V dimmers can also support a lot of LED lighting. But the application shortcomings are also very obvious. The low-voltage control signal requires an additional set of lines, which greatly increases the requirements for construction.

3. Trailing edge phase cut (RPC) MOS tube dimming, Back-edge phase cut control dimming

The trailing edge phase cut control dimmer is made of field effect transistor (FET) or insulated gate bipolar transistor (IGBT) devices. The trailing edge phase-cut dimmer generally uses MOSFET as a switching device, so it is also called MOSFET dimmer, commonly known as "MOS tube". MOSFET is a fully controlled switch, which can be controlled to be on or off, so there is no phenomenon that the thyristor dimmer cannot be completely turned off. In addition, MOSFET dimming circuits are more suitable for capacitive load dimming than SCRs. However, due to the high cost and the relatively complicated dimming circuit, it is not easy to stabilize and other characteristics, so that MOS tube dimming methods have not been developed. SCR dimming Optical devices still occupy most of the dimming system market.

Compared with the leading-edge phase-cut dimmer, the trailing-edge phase-cut dimmer is applied to LED lighting equipment. Since there is no minimum load requirement, it can achieve better performance on a single lighting equipment or a very small load. However, Since MOS tubes are rarely used in dimming systems, they are generally only made as knob-type single-lamp dimming switches. This low-power back-cut phase dimmer is not suitable for engineering. Many LED lighting manufacturers use this dimmer to test their own dimming drivers and lamps. Then push its own dimming products to the engineering market, leading to the situation of phase-cut dimming drive after modulating with the thyristor dimming system in the project. The mismatch of this dimming method leads to dimming flicker, which can quickly damage the power supply or dimmer.

4. DALI (Digital Addressable Lighting Interface)

The DALI standard has defined a DALI network, including the largest 64 units (independent addresses), 16 groups and 16 scenes. Different lighting units on the DALI bus can be flexibly grouped to achieve different scene control and management. In practical applications, a typical DALI controller controls up to 40 to 50 lights, which can be divided into 16 groups and can process some actions in parallel. In a DALI network, 30-40 control commands can be processed per second. This means that the controller needs to manage 2 dimming commands per second for each lighting group. DALI is not a real point-to-point network, it replaces the 1~10V voltage interface to control the ballast. Compared with the traditional 1-10V dimming, the advantage of DALI is that each node has a unique address code, and with feedback, the dimming at a longer distance will not have signal attenuation like 1-10V, but this distance is still should not exceed 200 meters.

Obviously DALI is not suitable for LED lighting control. A DALI network can only control 21 full-color LED lamps. DALI is oriented to traditional lighting control, focusing on the static control and reliability, stability and compatibility of the system. The scale of the LED lighting system is much larger than that of the DALI system. It mainly pursues the artistic expression of lamps and lanterns, and appropriately takes into account the intelligence of the system. This requires the system to be connected to a larger bus network, with unlimited expansion capabilities and higher scenarios. Refresh ability. Therefore, DALI systems are often incorporated into other bus systems as a subsystem in large-scale lighting projects.

The advantages of DALI dimming need not be repeated, but the disadvantages are still annoying signal line layout and high price. It is worth mentioning that the current DALI dimming driver still needs standby power consumption when turning off the lights in order to ensure that the microcontroller is always on standby.

5. DMX512 (or DMX) dimming

The DMX512 protocol was first developed by the USITT (American Theater Technology Association) to control the dimmer from the standard digital interface used in the console. DMX512 surpasses the analog system, but it cannot completely replace the analog system. The simplicity, reliability (if it can be installed and used correctly) and flexibility of DMX512 make it a protocol of choice when funds permit.

In practical applications, the control method of DMX512 is generally to design the power supply and the controller together. The DMX512 controller controls 8-24 lines and directly drives the RBG line of the LED luminaires. However, in the building lighting project, because the DC line is weak, it is required to install a controller at about 12 meters, and the control bus is in parallel mode. Therefore, the controller has a lot of wiring, and in many cases it can't even be constructed. The DMX512 receiver needs to set the address so that it can clearly receive the dimming command, which is also very inconvenient in practical applications. Multiple controllers are interconnected to control complex lighting schemes, and the design of operating software will be more complicated. Therefore, DMX512 is more suitable for occasions where LED lamps and lanterns are grouped together, such as stage lighting.

In summary, the main disadvantage of the DMX controller is that it requires a special wiring layout and type, and a certain programming is required to set the basic colors and scenes, which will cost a lot of later maintenance.

Related products

ARQ Series Shoebox LED lights, UL DLC listed, 100W-400W, 5-10 Years Warranty, 100-480VAC, 140-200lm/W

► UL/cUL/SAA/FCC/CE/Rohs Approval

► DLC 5.1 Premium

► Photocell, Daylight harvest, Microwave Sensor, 0-10V Dim Optional

► Multi-Voltage: 100-277V/100-347V/480Vac

► 100W-400W, 140-200 lm/W

► IP66, 5-10 years warranty

Subscribe

We will share with you our latest product info or LED industy info. Thanks.